Capabilities

Manual and Automated/Robotic MIG & TIG Welding

At Proform Group Inc., we offer manual and automated or robotic MIG and TIG welding to fabricate fuel tanks. Automated or robotic welding uses robots to maximize the speed, precision, and quality of the final product. It eliminates the errors and inconsistencies that result from manual welding.

MIG and TIG welding both use electrical currents to melt base materials together, forming a single solid joint when cooled.

TIG Welding

Tungsten inert gas (TIG) welding is a versatile welding process that joins metals with a non-consumable tungsten electrode. The electrode welds the base metals together with or without filler material.

TIG is slower than MIG and often results in longer lead times and higher production costs. However, customers are rewarded with higher quality results. TIG welders receive special training to achieve the high level of control, precision, strength, and appearance required for this welding process.

MIG Welding

Metal inert gas (MIG) welding uses a consumable wire as both electrode and filler material. This process is generally used for thick and large materials.

MIG welding is faster than TIG welding. Therefore, it has a low production cost and shorter lead times. MIG welding is easier for welders to learn and can produce sufficient results without much post-process finishing or cleaning. However, MIG welding doesn’t produce welds as strong, precise, and aesthetically pleasing as those produced by TIG welding.

MIG and TIG welding can be performed with a variety of metals, such as carbon steel, aluminum, and stainless steel. Generally, MIG welding is for thick metals and TIG welding is for thin materials.

Automatic 5-Axis Fiber Laser Cutting With Fully Integrated Fabrication Shear & Brake Presses

Fiber laser cutting is a metal cutting method that uses a fiber laser light created by diodes. The fiber optic cable focuses the light to make a precise cut into the substrate. Proform Group Inc. uses this cutting process for its many benefits:

- Increased uptime and throughput

- Lower operating costs

- Better quality

- Precise and repeatable results

- Reduced material waste due to no-contact cutting

- Minimal maintenance

- Easy to automate and maximize productivity

Fiber laser light cutting is twice as efficient as carbon dioxide lasers. Fiber laser cutting machinery is also simpler, as it does not require optical mirrors. Unlike traditional CO2 lasers, the focusing lens of the fiber laser is inside the cutting head and is not consumable.

We also have automatic shear and brake presses to cut and bend sheet metals into precise forms.

Automatic Feed Powder Coating & Chemical Etching

At Proform Group Inc., we offer powder coating and chemical etching services for fuel tank fabrication.

Powder Coating

Powder coating involves spraying a powder of a particular color on a metal surface, which has an electrical charge. The electrical charge adheres the powder to the metal surface, and once baked, the powder coating is permanent.

Many fabricators prefer powder coating due to advantages such as:

- Exceptional durability and longevity

- Cost-effectiveness

- Environmentally friendly

Chemical Etching

This process uses chemical etchants to selectively and precisely dissolve metal materials, producing the desired pattern or component. Chemical etching is preferred for its ability to retain the metal’s properties and achieve burr-free, stress-free parts with no heat-affected zones.

The benefits of this process include:

- Low-cost digital tooling

- Cost-effectiveness

- High accuracy

- Faster compared to laser, waterjet cutting, and stamping

These benefits make chemical etching suitable for extreme environments such as aerospace applications.

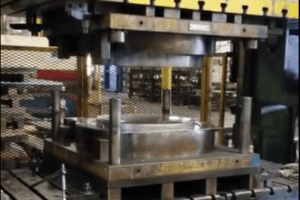

Stamping Presses

Metal stamping is a process where a machine uses a mold to shape metals into particular shapes. The specific process varies depending on the end product, but generally, it uses a stamping die and stamping press to cut different shapes out of sheet metal. Metal stamping is precise, cost-effective, and consistent.

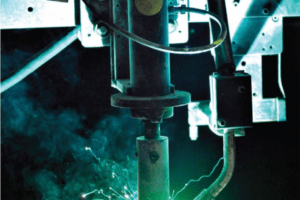

Plasma Cutting

Also called plasma arc cutting, plasma cutting uses a focused jet of ionized gas at about 20,000 °C to melt materials away from a cut. Operators strike the electric arc between the electrode and the workpiece. The electrode is set in an air- or water-cooled nozzle, which narrows the arc and creates a high-temperature, high-velocity plasma jet.

Plasma cutting provides the following benefits:

- It is five times faster than manual torches, cutting up to 500 inches every minute.

- It makes precise cuts in various metals—aluminum, steel, and more—of varying thicknesses.

- It keeps the substrate surface cool despite the high temperature of the plasma jet. This prevents damage to the metal and its coatings.

Rapid Prototyping

Rapid prototyping is a quick fabrication process that uses 3D computer-aided design (CAD) technology. Designed to model and test part functionality, prototypes are often created via additive manufacturing, or 3D printing.

Rapid prototyping offers the following benefits:

- Reduced time to market

- Ability to test and improve products

- Cost-effectiveness

Fuel Tank Fabrication for the Commercial Vehicle Industry

Fuel tank fabrication requires high-quality manufacturing equipment and expertise to guarantee the best products. Proform Group offers automated welding, fiber laser cutting, powder coating, chemical etching, metal stamping, plasma cutting, and rapid prototyping to develop and fabricate the best quality fuel tanks. These processes enable us to fabricate custom tanks according to our customers’ specifications. For more information about our products and services, please contact us.